Asset Classification: Asset Class, Types and Variations

In the complex world of heavy asset industries, where every hour of production is critical, some foundations are so fundamental they can become invisible. We focus on optimizing schedules, managing costs, and pushing for reliability, but often overlook the very language we use to define the assets we manage. The Asset Classification structure, the definitive blueprint of what your asset truly is, is one such foundation

For many mature operations, this structure was set during an initial CMMS implementation and then slowly eroded over time. For others, it was never formally established at all. This isn’t a minor administrative oversight; it’s a strategic vulnerability. Without a common asset language, your data becomes fragmented, your strategies become siloed, and your most critical business decisions are made with a distorted view of reality.

In our experience working with major mining and heavy asset clients, asset classification was either loosely defined, locked inside old spreadsheets, or left to be interpreted by different departments based on what made sense for their own needs. We have seen firsthand how architecting this foundational language transforms an operation. It’s about moving beyond simple labels to instill a deep, unified understanding of your physical assets, creating a powerful current of clarity that flows from the plant floor right through to the executive boardroom.

The Layers of Asset Classification

A foundational asset classification framework is layered, scalable, and easy to interpret across the organisation. It allows for a common understanding of assets regardless of role, whether you’re in engineering, maintenance, finance, procurement or operations.

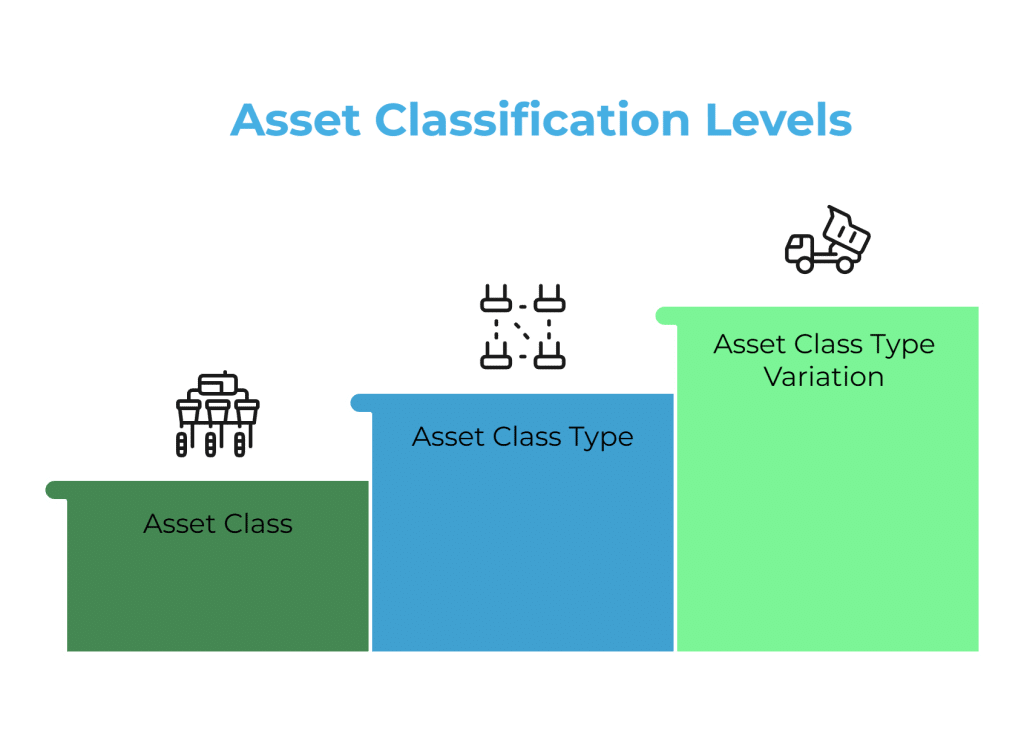

At a fundamental level, the classification is built across three primary tiers as per below, for mining environments, and can be adapted accordingly for other heavy asset industries:

Asset Class:

This is the broadest layer that groups assets by what they generally do, or in other words what their generic function is, in the operation. For example: Crushers, Mills, Conveyors, or Trucks. It provides a quick and simple way to group and compare performance across similar kinds of equipment.

Asset Class Type:

This next layer provides crucial specificity, within each asset class, of how assets can differ in how they perform their function and their design configuration differences, yet combination of their functions aligns to the same generic function of the asset class. A Conveyor as an asset class can contain types like Belt Conveyor and Bucket Elevator. This level helps distinguish operational differences and allows grouping them to understand the processes they are used for in an organisation.

Asset Class Type Variation:

This is the granular and often most valuable layer in asset classification. Depending on the complexity of the classifications, this level can sometimes be applicable for defining your asset class type further or sometimes the asset classification can stop at asset class type level and to enable consistency in use of three levels in a standardised manner, one can choose to define this level with names such as “Generic” or “Variation 1”. This level also captures further differences in design configuration from their respective asset class types, yet combination of them aligns to the same generic function of the asset class type. For a Bucket Elevator, variations can be a Chain Bucket Elevator versus a Belt Bucket Elevator. While both perform similar functions, their design configurations are different and their operating context would be different, eg one can be for heavy loads and the other can be for light to medium loads. The real integrity of this structure, however, comes from documented definitions and explicit boundary limits, that can be defined at the asset class type level or asset class type variation level. This is the constitution that governs your asset language. Without these documented rules, ambiguity thrives, and the entire structure loses its power.

The real integrity of this structure, however, comes from documented definitions and explicit boundary limits, that can be defined at the asset class type level or asset class type variation level. This is the constitution that governs your asset language. Without these documented rules, ambiguity thrives, and the entire structure loses its power.

A Foundation for Functional Location Hierarchies

Asset classification provides the “what”, but just as critical is understanding the “where”. A robust classification structure lays the groundwork for developing an equally strong Functional Location Hierarchy, which is used to map out where each asset sits within the operation, and what role it plays within that process.

This is why asset classification and functional location hierarchy are tightly linked. In our approach, we always ensure that asset classes are defined before assigning them to functional locations. This ensures assets are positioned correctly within both the operational process and the digital ecosystem, particularly in Computerised Maintenance Management Systems (CMMS).

To dive deeper into this structure and why it matters, see our related blog: Functional Location Hierarchies: A Foundation for Operational and Data Excellence.

Why Asset Classification Matters in Day-to-Day Operations

In theory, many businesses know they need a standardised way to classify assets. In practice, however, classification often grows organically. This results in scenarios where the same piece of equipment is classified in three different ways across three sites. Or where planners cannot find the right spare part because it’s buried under an incorrectly named tag.

We’ve seen reliability engineers spend weeks trying to gather failure data on a specific pump model across multiple sites, only to realise they were comparing different equipment due to inconsistent naming. By helping the client implement a standardised classification library across all operations, the same engineer could run a report in minutes and take a single improvement strategy company-wide.

Poor classification creates hidden cost drivers:

- Duplicated spare part inventories

- Inaccurate cost roll-ups

- Missed reliability trends

- Disconnected maintenance strategies

But when the classification is accurate and consistent, businesses are able to:

- Link and scale failure modes and maintenance strategies to similar assets

- Scale and improve opportunities from defect elimination, technological advancements, compliance management and operating benchmark processes across the business

- Standardise Bills of Materials (BoMs) and spares management

- Benchmark performance across sites and projects

Setting It Right from the Start: Greenfield vs Brownfield

Greenfield Projects: Engineering with a View to Sustain

In greenfield projects, everything starts from a blank page. This is an enormous opportunity to embed sustainability and data integrity into the system from day one. By implementing a complete asset classification system during design and operational readiness phases, engineering, procurement, and CMMS teams can load clean data, pre-approved BoMs, and maintenance templates well before operations begin.

This not only supports faster commissioning but also saves future costs in CMMS remediation and prevents data quality issues that typically take years to fix.

Brownfield Operations: Re-aligning a Disjointed Past

In existing sites, asset classification often suffers from years of legacy systems, site mergers, rushed project handovers, and undocumented standards. We’ve worked with clients who inherited equipment libraries where atleast 20% of entries were duplicates with different names eg Screw Conveyor and Screw Feeder when they both were the same after performing due diligence at their functional location levels and SME confirmations, or carried inconsistent class names due to no documentation and governance models in place.

During the mergers of mining companies, without documentation and governance teams, and adding the factor or project budgets and timelines, the opportunities to create new asset classes, types or variations are very easy and this again can cause similar non-standardisation as mentioned above.

A classification standardisation effort isn’t just about cleaning up data. It’s about giving the business a fresh lens through which to view, manage, and optimise assets. Once standardised, asset libraries become a source of truth that reduces inefficiency and unlocks better decision-making across maintenance, procurement, engineering, and finance.

Sustaining the Asset Classification Structure

An asset classification framework is not a one-off project. It requires:

- Clear ownership and governance

- Documented functions/definitions and boundary limits

- Rules for creating and reviewing new asset classes

- Training for teams on how to apply the structure

- System alignment across CMMS, ERP, and planning tools

The more aligned this structure is across the business, the more resilient the asset data becomes, especially when systems change, new projects emerge, or workforce turnover occurs. Not forgetting the rise of artificial intelligence in today’s era, where well defined structures can be leveraged to improve the quality and efficiency of the outcomes and sustain standardisation with greater accuracy.

In our engagements, we’ve seen some businesses hold on to good classification practices during initial stages but slowly drift away due to lack of documentation, system incompatibilities during mergers, change in business priorities and governance teams dispersed to other roles, or simply because key team members with historical knowledge leave the business. Others continue to rely on spreadsheet-based lists with no real CMMS integration. Eventually, when asset libraries are updated, they diverge from the original standard, breaking the foundation that good maintenance and planning is built on.

This is why we always advocate for proper governance and automation guardrails in the CMMS, ensuring that classification logic is applied consistently across asset lifecycles, regardless of who enters the data or which project it comes from.

Define Your Assets Classifications for Sustainability, Standardisation and Adaptability

Understanding exactly what each asset is, how it differs from others, and how it fits into your broader operational landscape – is gaining competitive advantage. Asset classification is not a back-end exercise, it is a strategic capability.

For those building from scratch or trying to fix legacy systems, investing time in setting up a scalable and logical classification structure will return value for years to come. And when tied closely with functional location hierarchies, it lays the groundwork for data quality, operational efficiency, and sustainable asset performance.

Shivaan Asset Management partners with asset-intensive businesses through this foundational step, transforming unstructured asset records into structured systems that support performance, compliance, and digital evolution. Whether you’re tackling legacy issues in brownfield environments or building greenfield operations from scratch, your asset structure is not just a tool – it’s a competitive advantage.