Equipment Hierarchy Development: An Anatomy of Asset Knowledge, Intelligence and Standardisation

In heavy asset industries, managing complex machinery requires more than just a list of assets. It demands a structured understanding of how those assets are functionally built, maintained, and operated. While asset classification tells us “what” an asset is, and functional location tells us “where” it is, it is the equipment hierarchy that provides further clarity and granularity on “how does it function, and how can we manage it systematically”.

This content continues from our earlier discussions on asset class, types and variations, and functional location hierarchies. Here, we explore the third foundational pillar of asset knowledge and standardisation as a key practice area within the asset management system: the development of standardised and functional equipment hierarchies.

What Is an Equipment Hierarchy?

An equipment hierarchy is a logical, functional breakdown of an asset, from the complete unit down to its maintainable components and parts. This structured tree reflects how an asset is designed to perform its function and where failure can occur. Unlike a flat list of parts or location-based tagging, an equipment hierarchy organises every level of the asset, from systems, assemblies to components, built on their functional support blocks and relationship.

This hierarchy is not the same as a functional location. Functional location is like the GPS, it defines where the asset is located within the site or process. The equipment hierarchy, however, is the engineering architecture that describes how the asset is functionally designed and built, that provides clarity of what it is made up of.

The Purpose and Value of Hierarchy Development

Developing an equipment hierarchy serves several purposes:

Establishing a shared technical language across all departments

Providing a sustainable foundation for asset data standardisation

Supporting standardised FMEA or RCM analysis, hence standardisation of naming in the work execution packages

Enabling correct development of standardised functional locations and associated Bill of Materials (BoMs)

Enhancing AI-readiness for future tools and technologies

More importantly, it creates the foundation that supports operational excellence, digital transformation, and cross-functional decision-making.

Standardisation Across All Equipment: Critical to Success

A common mistake in hierarchy development is tailoring the depth or structure of the hierarchy based on the asset’s perceived criticality or size. For example, people may believe that a small gearbox that is often replaced doesn’t need a detailed breakdown, while a larger one does. Or they may argue that because a pump is classified as non-critical, its hierarchy should stop early.

This thinking is flawed and counterproductive, and generally seen when their is no process or understanding on the value of data or reduced desire to understand. An equipment hierarchy can be built as a library for a single asset class type variation and component levels can be adjusted to suit for specific equipment.

At the hierarchy development stage, the goal is not to decide what a specific equipment’s criticality, risk or maintenance tasks are required, it is to standardise data from a generic equipment point of view. Operational decisions come later through failure analysis and maintenance strategy development. The hierarchy is a technical blueprint, not a maintenance plan.

Once the structure is standardised, different strategies, such as run-to-failure, preventive maintenance, or condition monitoring, can be developed based on equipment’s specific function to the process its designed to operate in, risk appetite, operational failure, criticality and spares availability. That’s when the failure modes, risk assessments, and criticality analysis guide decisions. The same hierarchy can therefore support multiple maintenance strategies across different operational scenarios.

A Systematic Development Process: The 80:20 Rule

Hierarchy development begins at the Asset Class Type Variation level, recognising that different design variants of an asset require distinct breakdowns. A generic, standardised hierarchy is built at this level, covering around 80% of typical equipment design. This becomes the template for all identical or similar assets across the organisation.

The remaining 20% involves refining the template to match the actual installed asset, such as specific model differences, minor differences in components or unique design features. This customisation becomes part of business-as-usual activities managed by a governance team.

This 80:20 method reduces duplication, ensures repeatability, and enables building a robust database where the teams are then able to further improve the data to their business requirements and with the pattern then seen on data, it becomes even clear and easier to convert the data into codes for the CMMS and apply them like a template.

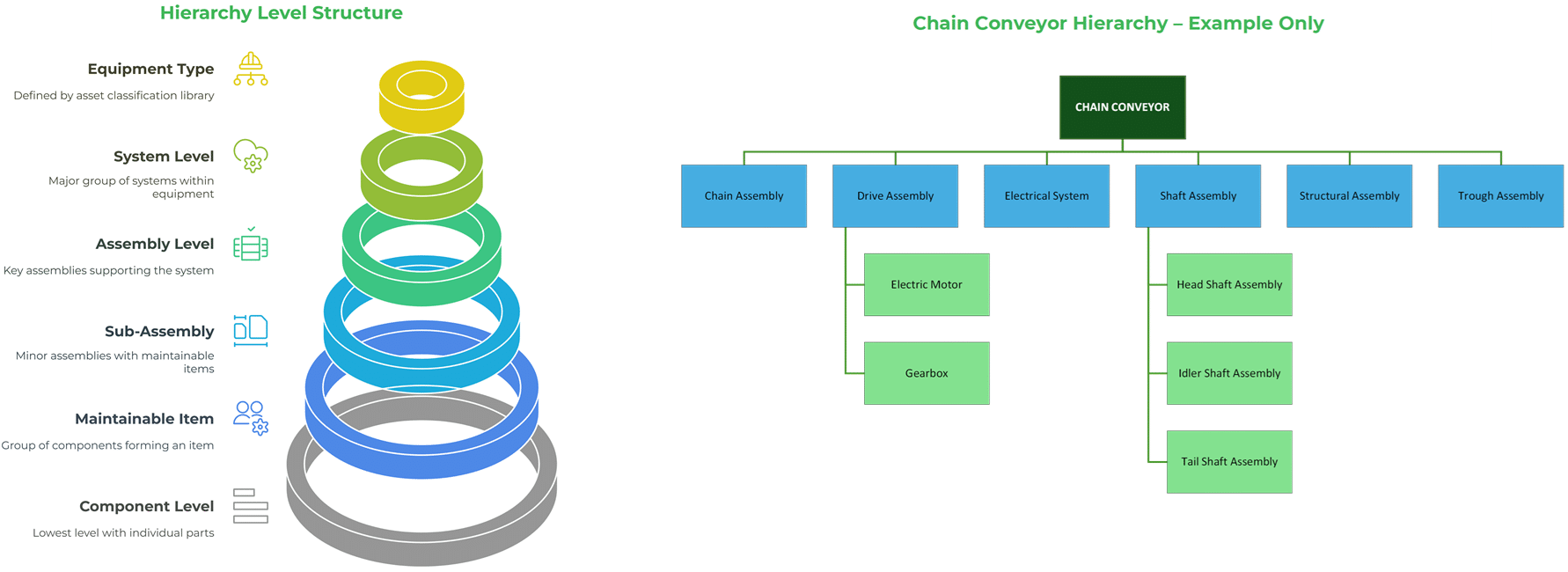

Recommended Hierarchy Level Structure for Heavy Asset Industries

While each equipment’s hierarchy breakdown can differ, a typical structure for a complex equipment, say for an equipment in mining industry like Draglines, Car Dumpers, Reclaimers, Stackers, etc, includes:

Equipment/Asset Class Type Variation – Defined by asset classification library eg. Electric Haul Truck

System Level – Major group of systems within an equipment eg Hydraulic System, Power Train

Sub-System or Assembly Level – Key assemblies supporting the system eg Brake Assembly

Sub-Assembly Level – Minor assemblies that contains multiple maintainable items eg Pumping Assembly,

Maintainable Item Level – Last parent levels in the hierarchy where group of components make up the maintainable item level. Eg Pump, Gearbox, etc

Component or Part Level – The lowest practical or agreed level or last children level in the hierarchy (e.g., Impeller, bearings, shaft, seal)

Depending on the simplicity or complexity of the equipment or asset class type variation, some levels may not be required and sometimes an additional level needs to be strategically created to enable the children level to have a meaningful contribution of their functions to the parent level.

Key Considerations When Developing Equipment Hierarchies

1. Function-Driven Logic

Each parent level must be functionally supported by its children. The breakdown must follow the logic that all children together fulfill the parent’s function. This is foundational systems engineering thinking.

2. Avoid End-Use Bias During Development

One of the most misunderstood areas is allowing the end-use of the equipment to influence hierarchy design. For instance, if one pump is monitored and maintained while another of the same type is routinely replaced due to low cost or perceived criticality, teams may feel they should stop the hierarchy early for the latter. This defeats the purpose.

The hierarchy’s job is not to determine what will be done with the equipment, it is to create a standardised structure for all of them. Once failure analysis and task development begin, the real decisions around what needs maintenance and what doesn’t will follow, based on actual risk and failure data.

This means the same pump, regardless of size or criticality, should follow the same hierarchy, with allowance to adjust the components but the maintainable item remains the same regardless for data standardisation purpose. The same naming conventions and logic should be applied. This uniformity is what enables powerful scaling, benchmarking, and governance across the business.

This separation of concerns is crucial. A hierarchy built with inconsistent depth or logic across similar equipment will lead to data fragmentation, misinterpretation, and unreliable analysis later.

Transformational Business Benefits

✓ Scaling Improvements with Minimal Effort

When an improvement is validated on one asset, be it a design change, a better task, or a more reliable part—the standardised hierarchy makes it possible to find every similar asset’s information across the business. The improvement can then be rolled out enterprise-wide with minimal cost and time, creating unified uplift across departments.

✓ Enhanced Inventory and Work Management

Standardised hierarchy supports accurate BoMs, task list links and correct work reporting levels at the correct functional location level. This reduces incorrect part orders, enhances spares planning, builds correct data capture in CMMS and improves technician confidence.

✓ Better Criticality and Risk Analysis

Hierarchies allow for bottom-up criticality assessments. Individual part risks can be rolled up, enabling more accurate, dynamic, and transparent risk profiles. Many operations make one-time, top-down criticality decisions at the equipment level that are never/hardly revisited. Hierarchical data allows reassessment and justifies budgets with confidence.

✓ AI-Readiness and Lower Cost of Intelligence

Many organisations today invest heavily in AI, NLP, and LLM technologies to extract insights from messy and unstructured maintenance data. This comes with high cost and long lead times, due to inconsistent terminologies, local slangs, or naming mismatches.

With standardised data structures—hierarchies, maintainable item names, failure modes—these challenges are largely eliminated. AI learns faster, delivers insights sooner, and requires far less custom configuration. Work order data becomes useful, not just available.

Why It Matters: Strategic Value Across the Business

A standardised equipment hierarchy touches every corner of the organisation:

Finance: More accurate cost roll-ups, investment justifications with transparent and clean historical records, and clearer asset lifecycle tracking

Maintenance Planning & Scheduling: Reduced duplication of task plans, improved task logic, safety requirements, special tooling and contractor requirements and rapid improvement applications across similar assets

Reliability Engineering: Faster failure analysis, maintenance task optimisation, root cause analysis, clear line of sight for criticality and risks, and rapid continuous improvement deployments

Operations: Clarity on system availability, better planning for yearly production budgets to meet customer demands, and visibility of equipment health across systems and sites

Supply Chain: Visibility and control over spares and part standardisation, or strategic business opportunities to hold common spares at a common warehouse for sites that are close to each other

Executives: Transparent, data-driven insights that link strategy with execution

Governance: Sustaining the Foundation

A strong hierarchy requires ongoing stewardship. Dedicated governance ensures:

Improved collaboration between Design, Engineering, Operations, Reliability Engineering and Vendors, as a minimum, are always maintained

New assets follow existing templates

Variations are approved and tracked

Naming conventions are applied consistently

Changes are documented and reviewed

This creates not just a one-time system, but a living knowledge asset that matures with the business.

Strategic Asset Management Enabler

In heavy asset industries, equipment hierarchies are not just technical documentation—they are an essential foundation for strategic asset management. They improve planning, reduce risk, drive standardisation, and prepare organisations for AI-driven transformation.

When developed and maintained properly, they help businesses make faster, better, and more consistent decisions—bridging the gap between technical details and enterprise-wide goals.

At Shivaan Asset Management, we help organisations design and embed these hierarchies to strengthen their foundations for reliability, intelligence, standardisation and operational excellence. This builds a competitive advantage for their business to enhance performance, break down silos and make their data an asset.