Functional Location Hierarchies: A Foundation for Operational and Data Excellence

In the world of heavy industries like mining, asset management is more than just keeping machines running. It’s about ensuring every asset is traceable, accountable, and aligned with how the operation performs. At the heart of this discipline lies a foundational concept that’s often misunderstood or overlooked: the Functional Location taxonomy/hierarchy.

This isn’t just a coding system for equipment. It’s a structured way to map and manage every asset in your business – by where it’s located, what it does, and how it supports broader operations. Done well, it becomes the underlying structure that allows data to flow cleanly, strategies to be executed precisely, and decisions to be made with confidence.

Why is Functional Location Hierarchy More Than Just a Code?

In a mining operation, there are hundreds of assets that operate in connection with each other physically or through processes. The mining asset classifications can range from heavy/medium/light mobile equipments, fixed plant, infrastructure, rail, and port and each classifications contain varied numbers of asset classes, types and variations, from dump trucks, underground shafts and winders, crushers, pumps, screens, conveyors and green energy generation assets like wind turbines and solar panels. Without a structured way to categorise and locate these assets, the plant floor and the boardroom would be speaking different languages. Maintenance teams would struggle to track work history, finance departments couldn’t roll up costs by system or area, and planners would be left juggling conflicting data.

That’s where the functional location hierarchy proves invaluable. It’s a logical structure, usually built into your Computerised Maintenance Management System (CMMS), that organises assets based on where they are, what function they serve, and how they connect to the broader process. It ensures that every equipment record isn’t floating in isolation but grounded in a meaningful operational context.

From an engineers understanding point of view – Functional location is a layered structure approach where the function defined for every level is able to be practically distributed from top-down and collective functions of lower levels contributes to its higher level.

With this framework, you can trace data from a single pump up through the system it belongs to, the area it operates in, and the site as a whole. This roll-up allows for meaningful business reporting, asset benchmarking, and cost analysis at every level.

But for all this to work, the structure must be designed with intention and maintained with discipline.

Functional Location Hierarchy Development: A Practical Example Approach

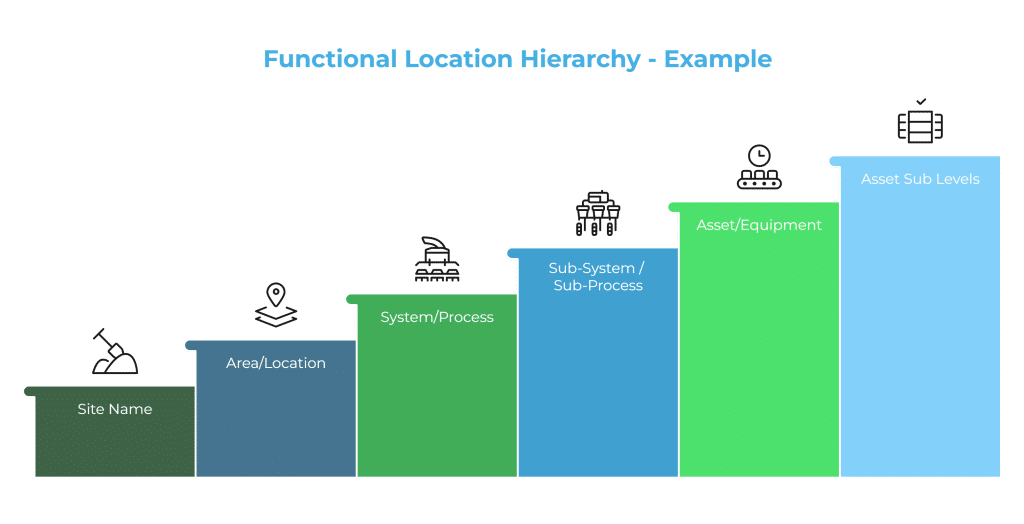

The example below highlights how we have supported our mining clients from a non-biased approach and enabling standardisation in their functional location hierarchy developments, and sustaining for all future projects, including design teams, operational readiness teams and business readiness teams during mergers. While structures vary between industries and even across businesses, the principles remain the same:

Level 1 – Site Name – The name of the physical mine or plant where operations take place.

Example: “Mining Site A”Level 2 – Area / Location – A geographical or operational section within the site.

Example: “Processing Area B”Level 3 – System / Process – The major group of process activities or systems that perform high-level functions within the area / location.

Example: “Ore Handling”Level 4 – Sub-System / Sub-Process – More refined sections of the process or plant systems.

Example: “Crushing Circuit” or “Power Distribution”Level 5 – Asset / Equipment – The actual item of equipment, with a standardised ID structure used across the business (e.g., Tag-ID, Serial Number, Location ID). This is also where the asset class types and variations shall be linked, to generate standardised Level 6 and beyond levels.

Example: “Primary Crusher PCR001”, “Conveyor CONV001”, “Storage Bin STRGBN003”, “Heat Exchanger Radiator HEXRDTR002”Level 6 – Asset Sub Levels – These are generally the assemblies, sub-assemblies and maintainable items, depending on the complexity of asset assembly.

Example: “Drive Assembly” or “Structural Assembly”

Key Considerations for Hierarchy Development

When developing an asset hierarchy, it’s vital to:

- Define Clear Boundaries: Each asset class and its variations must have well-documented definitions and boundary limits to prevent overlap or misclassification. This ensures that different asset classes are not inadvertently nested within others.

- Align with CMMS Design: A thorough understanding of the business’s Computerized Maintenance Management System (CMMS) and its design is essential. This understanding directly influences how the functional location hierarchy is configured within the system.

- Document Each Level: Every level of the hierarchy should be clearly defined and documented. This ensures that all business functions, from maintenance to finance, can interpret and utilize the data consistently.

Benefits of a Standardized Approach

Linking equipment to consistent functional locations and standardized asset classification libraries offers significant benefits:

- Reusability: Common maintenance strategies, failure mode analyses, spare parts lists (Bills of Material – BoMs), and procedures can be easily reused across identical assets.

- Efficiency: This approach eliminates duplication of effort, accelerates the training of new staff, and minimizes human error in planning and execution.

To illustrate, a five level functional location ID might look like:

Where lets take arbitrary codes for every level:

MSA = Mining Site A

PRB = Processing Area B

OH = Ore Handling

CR = Crushing Circuit

PCR01 = Primary Crusher #1

Level 5 Functional Location Code = MSA-PRB-OH-CR-PCR01

This structured ID tells you exactly where the asset is, what function it is supporting, and how it can standardise the knowledge and language for all members of the business to know where they can find any asset of interest, under what level, and what to search for.

Why Getting The Right Functional Location Matters

A well-built functional location hierarchy creates transparency across the organisation. It enables:

Accurate cost roll-ups for budgeting and investment decisions

Clear work order generation that reduces rework and confusion

Better governance and accountability in planning and execution

Repeatable asset strategies, reducing duplication of effort across sites

Streamlined maintenance, inventory, and reliability practices

But if the structure is inconsistent, outdated, or misaligned with how the plant actually operates, the opposite happens. Data becomes fragmented, comparisons become flawed, and teams waste time searching for answers rather than acting on them.

Greenfield vs Brownfield: Different Challenges, Same Opportunity

Whether you’re launching a new operation or managing an existing one, the need for a reliable hierarchy is the same, but how you approach it varies.

Brownfield Sites: Cleaning the Legacy to Unleash Potential

Existing operating plants often inherit inconsistent structures built over years of project work, acquisitions, or quick fixes. In these environments, similar assets might be listed with mix-match levels and some maybe redundant due to replacements and sometimes multiple codes for the same descriptions exists in the CMMS.

The opportunity here is to undertake a focused standardisation initiative. This doesn’t just “fix” the data, it transforms how the operation is viewed and managed. With a single, coherent view of all assets, teams can compare like-for-like performance, standardise maintenance strategies, and build accurate reports that align with business goals.

Greenfield Projects: Building Sustainability from Day One

In new projects, a well-planned functional location hierarchy is a critical enabler of operational readiness. When designed during the engineering and design phases, it sets the foundation for efficient CMMS builds, clean master data, and consistent planning logic.

This forward-thinking approach allows asset strategies and spare parts (BoMs) to be loaded and tested before commissioning begins. It also ensures that when the plant starts operating, the team inherits a logical and intuitive system – not one they need to fix under pressure later.

What Are The Impacts Across The Business

A strong functional location hierarchy benefits the entire organisation, not just the maintenance team:

Finance & Leadership can trust cost reports tied to real operational structures, enabling accurate budget planning and tracking.

Supply Chain & Inventory gain visibility into standardised parts across identical assets, reducing stock duplication and improving forecasting.

Reliability & Operations can pinpoint root causes effectively, assign responsibilities by area, improve, scale and standardise maintenance and operating plans, where applicable, and optimise asset performance consistently.

Engineering Teams designing assets can align equipment more precisely to operational zones and business needs. A consistent hierarchy allows them to apply naming conventions, technical documentation, and compliance standards more effectively – reducing operational readiness project delays and making it easier to develop designs that match field reality and stakeholder expectations.

- Safety & Compliance Teams are able to map the hazards, risks and compliance requirements accurately, and are clearly able to manage them at the true location levels without inundating multiple asset risks and hazard to one location. Compliance teams are able to load their standards and requirements for other departments to realise the needs when new projects are implemented or when there are workforce turnarounds.

Contractors & Service Providers benefit from the predictability of a consistent structure. When functional locations and naming rules are standardised across similar assets, external teams can quickly familiarise themselves with plant layouts, asset criticality, and access procedures – shortening onboarding time, reducing mistakes, and improving collaboration.

Data Analysts & Reporting Teams gain a powerful foundation for building insights. With clean, logical hierarchies, data isn’t buried in random locations or mixed under the same category. Analysts can trace inconsistencies, detect errors, and perform root cause analysis much faster – turning operational data into actionable intelligence.

Business-wide Competitiveness improves as decisions become faster, more accurate, and based on reliable data. Strategy and execution become aligned through shared systems, boosting agility and resilience in volatile environments.

Employee Experience & Retention also improves. A structured system reduces frustration from searching for data, minimises rework, and provides a learning path that reinforces best practices. Employees feel empowered, not burdened – leading to higher engagement, lower turnover, and a culture of continuous improvement.

Governance, Integrity, and Long-Term Success

Designing a good structure is only the beginning. What sustains it is governance.

A well-governed hierarchy includes:

Documented naming conventions and structure logic

Defined roles and responsibilities for updating and maintaining the hierarchy

Alignment across engineering, maintenance, IT, operations, and finance

Continuous reviews as the plant evolves

As operations move toward digital twins, machine learning, and advanced analytics, the strength of this foundational structure becomes even more critical. Poor structure leads to unreliable data, while good structure supports growth, innovation, and operational excellence.

Your Functional Location Structure Is Your Foundation in Asset Management

In asset-intensive industries, your functional location hierarchy isn’t just an internal classification – it’s a living framework that reflects how well your operation is understood, managed, and improved. When designed and maintained correctly, it becomes the anchor for every system and decision that relies on asset data.

Shivaan Asset Management partners with businesses to build taxonomies from the ground up – or restructure them where needed – ensuring they serve both operational needs and strategic ambitions. Whether you’re tackling legacy issues in brownfield environments or building greenfield operations from scratch, your asset structure is not just a tool – it’s a competitive advantage.